Thyssenkrupp Rothe Erde relies on saw technology from framag

Aktualisiert am: 24.08.2016 14:10

The requirements of thyssenkrupp Rothe Erde GmbH for the saw manufacturer from Frankenburg were clear: An old sawing system had to be replaced and the new saw needed to be integrated in the existing production line. The goal was to achieve a high level of process reliability and a good cutting result on quenched and tempered steels (e.g. 42CrMo4) and construction steels.

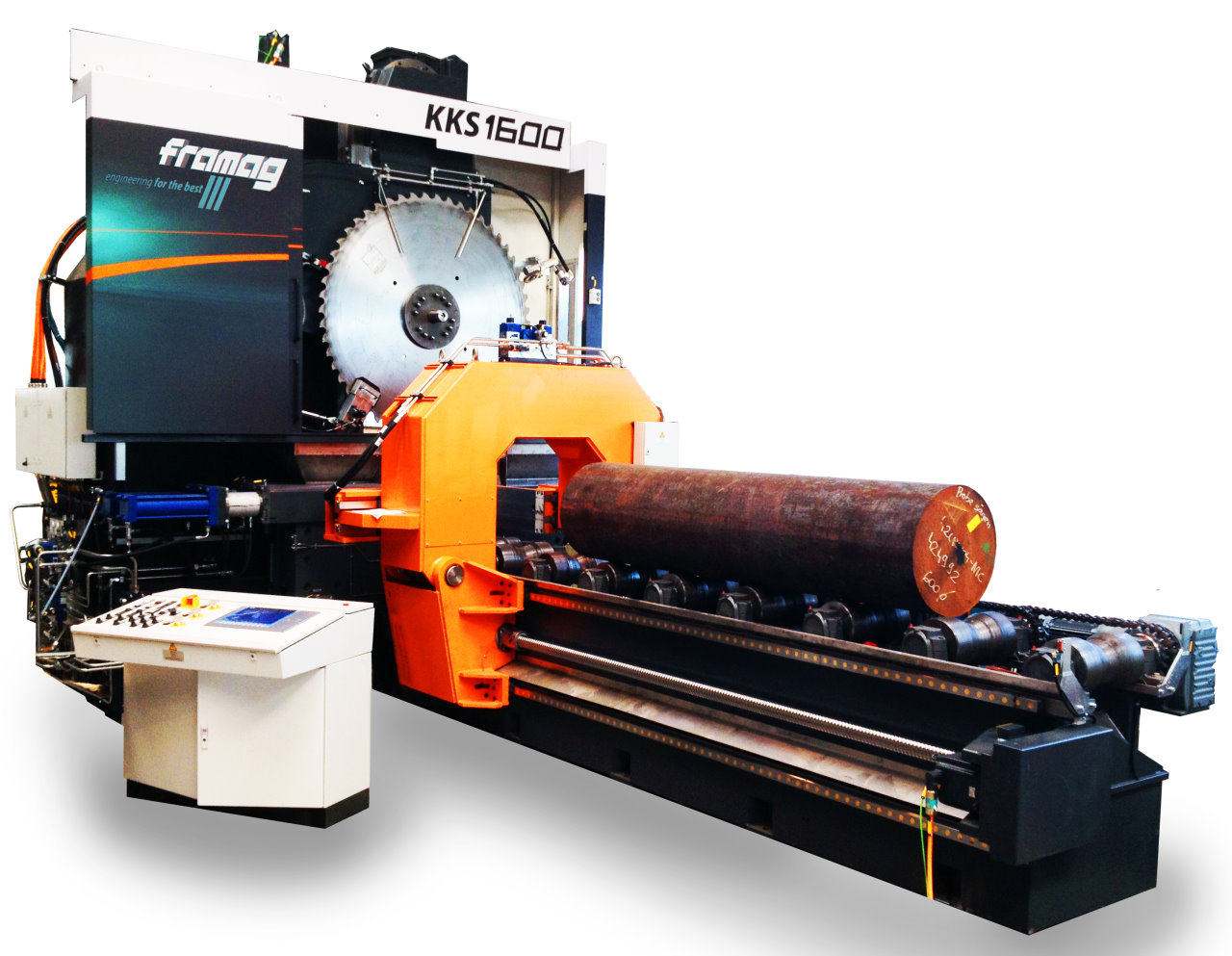

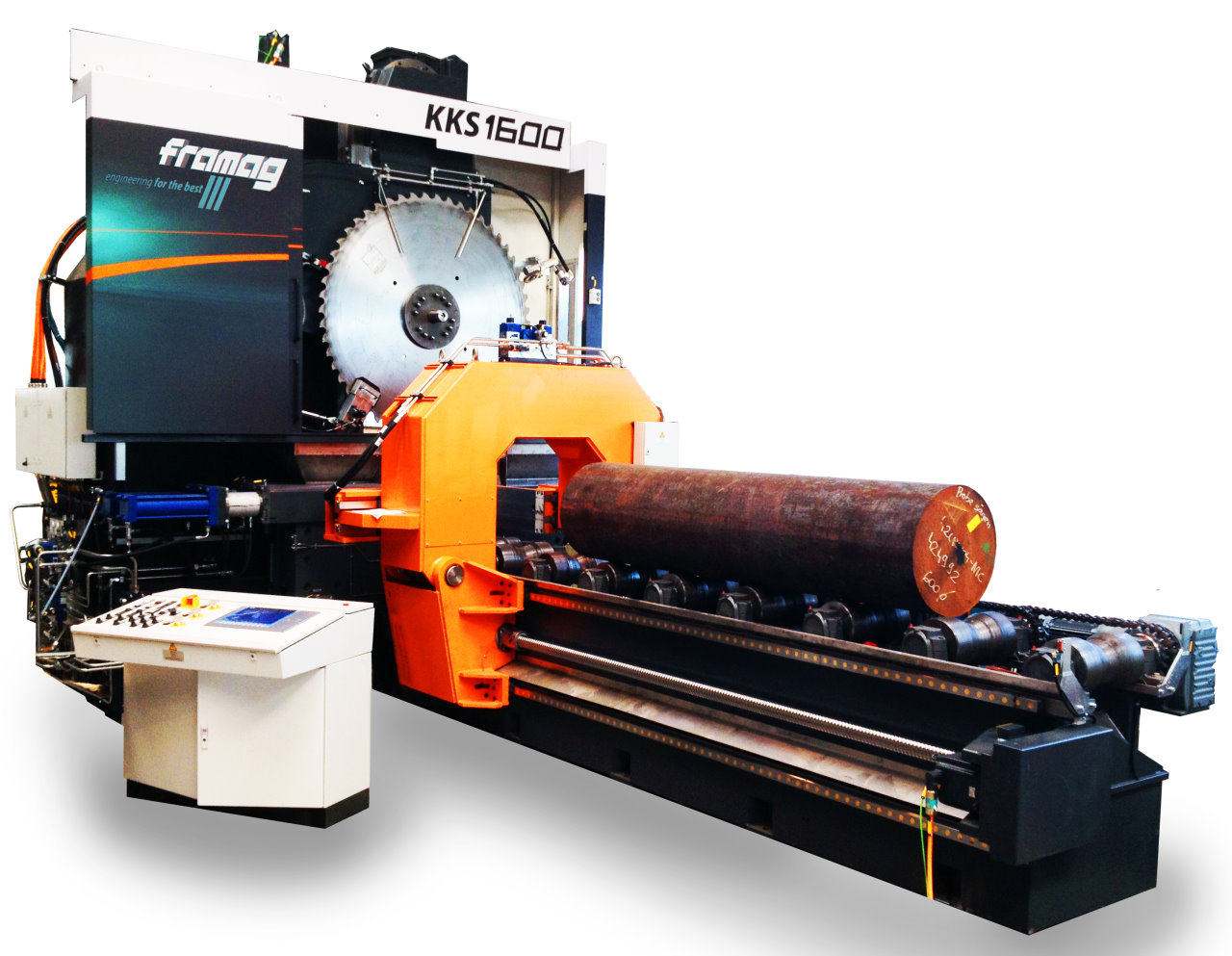

Using state-of-the-art technology, the colleagues at framag engineered a KKS 1600 cold circular saw that cuts round materials with a diameter up to 600 mm and a length of 6,000 10,000 mm precisely and reliably up to a maximum weight of 23 to (out-of-roundness up to 1.5 %). A special 3-point clamping device, combined with a table height adjustment system, supports the material optimally during cutting.

The newly developed hydraulic saw blade damping patented by framag improves the smooth running of the saw blade, which also has a positive effect on the service life of the saw blade. The cut becomes more even overall, with a minimal cut gap.

"framag is a competent partner. The communication in the project phase was very good and all our requirements were met to our complete satisfaction. The installation and commissioning were also carried out extremely professionally. The agreed acceptance criteria were met without any problems", says a delighted H. Tschich (Dr. Ing.) from thyssenkrupp Rothe Erde GmbH.

Using state-of-the-art technology, the colleagues at framag engineered a KKS 1600 cold circular saw that cuts round materials with a diameter up to 600 mm and a length of 6,000 10,000 mm precisely and reliably up to a maximum weight of 23 to (out-of-roundness up to 1.5 %). A special 3-point clamping device, combined with a table height adjustment system, supports the material optimally during cutting.

The newly developed hydraulic saw blade damping patented by framag improves the smooth running of the saw blade, which also has a positive effect on the service life of the saw blade. The cut becomes more even overall, with a minimal cut gap.

"framag is a competent partner. The communication in the project phase was very good and all our requirements were met to our complete satisfaction. The installation and commissioning were also carried out extremely professionally. The agreed acceptance criteria were met without any problems", says a delighted H. Tschich (Dr. Ing.) from thyssenkrupp Rothe Erde GmbH.